In the realm of networking and telecommunications, the choice of cabling can dramatically impact performance, cost, and durability. A common debate arises between copper cabling and CCA (Copper Clad Aluminum) cabling. Here, we delve into the drawbacks of each and explore the potential pitfalls when choosing CCA cabling.

Conductivity: The Weakness of CCA

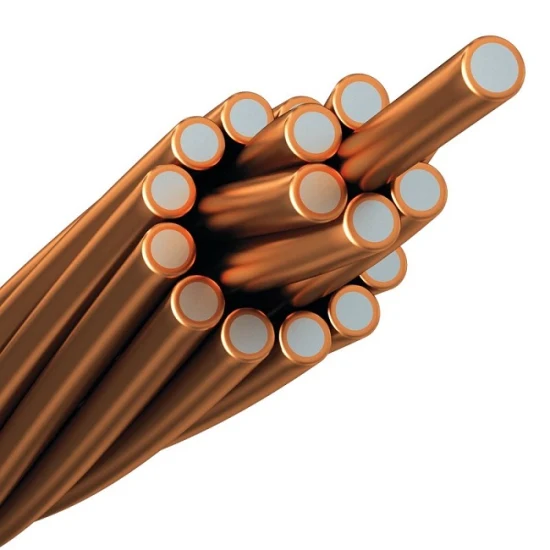

Copper is renowned for its high electrical conductivity, making it the superior choice for many applications. In stark contrast, CCA cables, with their aluminum cores, offer inferior signal transmission capabilities and suffer from significant signal loss over distances. This lower conductivity can result in poor performance, particularly in high-speed data transmission systems where maintaining signal integrity is crucial.

Cost Considerations: The Hidden Costs of CCA

While CCA cabling might seem appealing due to its lower upfront cost compared to pure copper, this perceived savings can be deceptive. The reduced performance and durability of CCA cables can lead to increased maintenance and replacement costs over time. For large-scale installations, these long-term costs can outweigh the initial savings, making CCA a less economical choice in the long run.

Weight: The Fragility of CCA

CCA cables are lighter than their pure copper counterparts due to their aluminum cores. However, this lightness comes with a trade-off in durability. The aluminum core is more prone to physical damage and breakage, which can lead to frequent failures and additional labor costs for repairs and replacements. The supposed ease of installation can quickly turn into a logistical headache.

Corrosion Resistance: The Susceptibility of CCA

In environments exposed to moisture or corrosive elements, the corrosion resistance of cabling is vital. Pure copper cables excel in this aspect, offering superior resistance to corrosion compared to CCA cables. The aluminum in CCA is more susceptible to oxidation and degradation, compromising the long-term reliability and performance, particularly in outdoor or harsh environments.

Compatibility Considerations: The Limitations of CCA

While CCA cables might be compatible with many applications, their lower conductivity often results in subpar performance. High-speed data transmission systems, for instance, may not function optimally with CCA cables, leading to reduced efficiency and potential data loss. This makes CCA a poor choice for applications requiring high performance and reliability.

Regulatory Compliance: The Risks of Non-Compliance

In certain regions or industries, regulations or standards may require the use of pure copper cables for specific applications. Non-compliance with these regulations can lead to significant risks, including legal penalties and compromised safety and reliability of the network infrastructure. Before opting for CCA cabling, it’s crucial to verify regulatory requirements to avoid potential pitfalls.

When evaluating copper cabling against CCA cabling, the trade-offs are clear. Although CCA cables may offer initial cost savings and lighter weight, their inferior conductivity, susceptibility to damage and corrosion, and limited compatibility with high-performance systems highlight their significant disadvantages.

Pierson Computing strongly advocates for the use of solid copper cabling due to its unmatched conductivity, durability, and broad compatibility. With Pierson Computing as your partner, you can confidently undertake your network infrastructure projects, knowing you are supported by a steadfast ally championing the superior performance and reliability of solid copper cabling.